Value proposition

Target Market

With the Asbeter AC Mineral process, we are targeting both the Calcium Silicate Hydrate market and the asbestos-cement processing market.

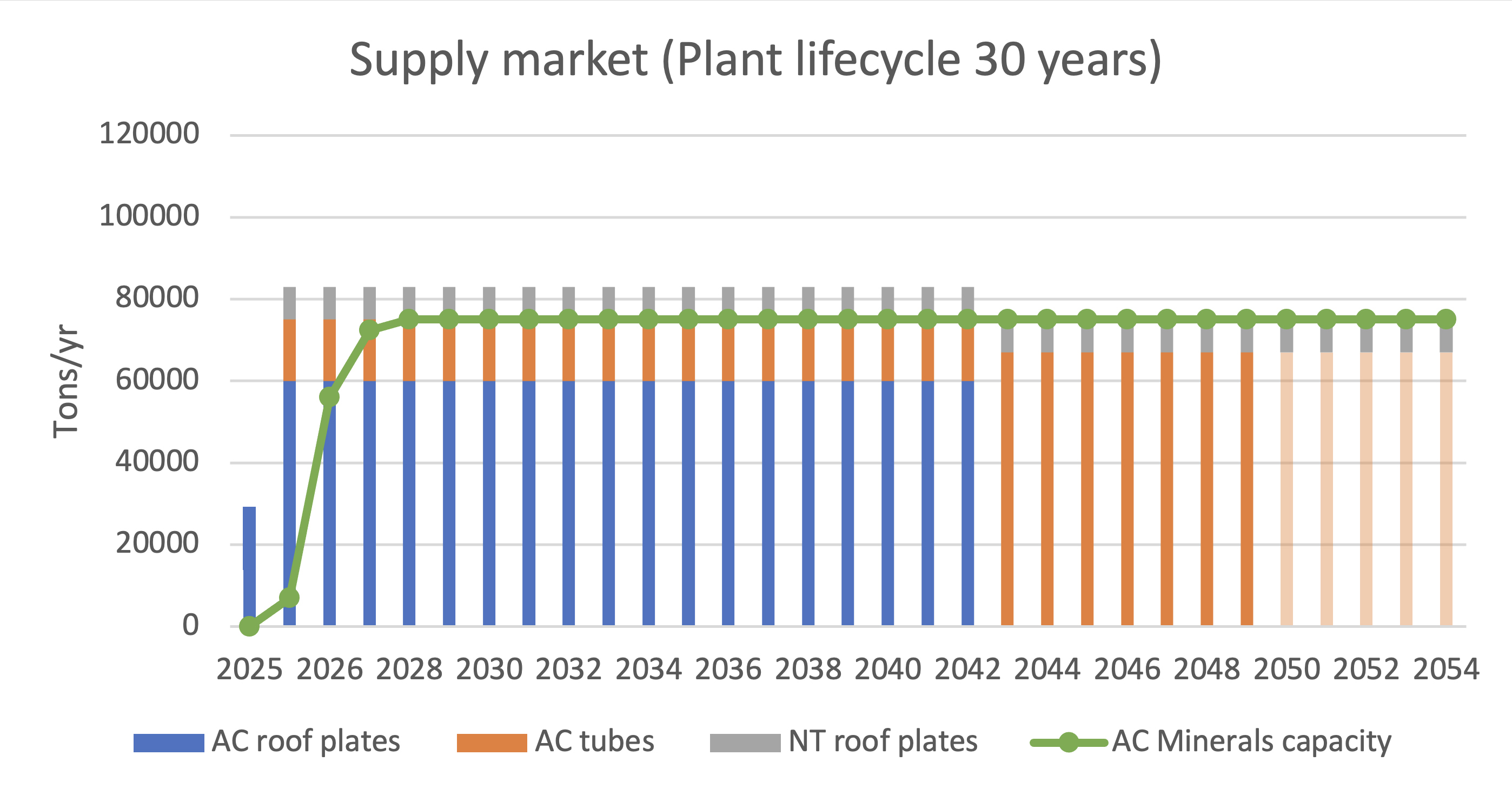

The value of the asbestos-cement processing market is difficult to determine exactly because it is not a regularly tracked statistic. However, there still are enormous amounts of asbestos cement in our living environment. Because of the increased awareness about the high costs for public health, there has been a declining demand for asbestos, and there has been a push for increased regulations related to the use of asbestos and asbestos-containing products. Coupled with Asbeter's AC Minerals process to fully destruct asbestos, we aim to solve the problem of asbestos in asbestos cement in the coming decades. Asbeter's AC Minerals flagship plant has a business case for asbestos cement in the Netherlands for at least 25-30 years.

The quantities of asbestos cement present in other European member states are considerably higher, so there is even more asbestos cement to be processed there. However, that does not mean that Asbeter's market would end. That is because Asbeter's AC Minerals is also suitable for processing non-asbestos cement and concrete waste, and for mineral wool fibres, which are expected to be blacklisted in the coming years and will thus need to be processed in a safe and (ideally) circular way. Our process is highly suitable to destruct those materials too. For this reason, the destruction of mineral wool fibres is included in our AC Minerals patent. We will further explore those other applications once we are well underway with tackling the asbestos problem, as asbestos is the most hazardous substance and thus poses the largest risk to public health and the environment.

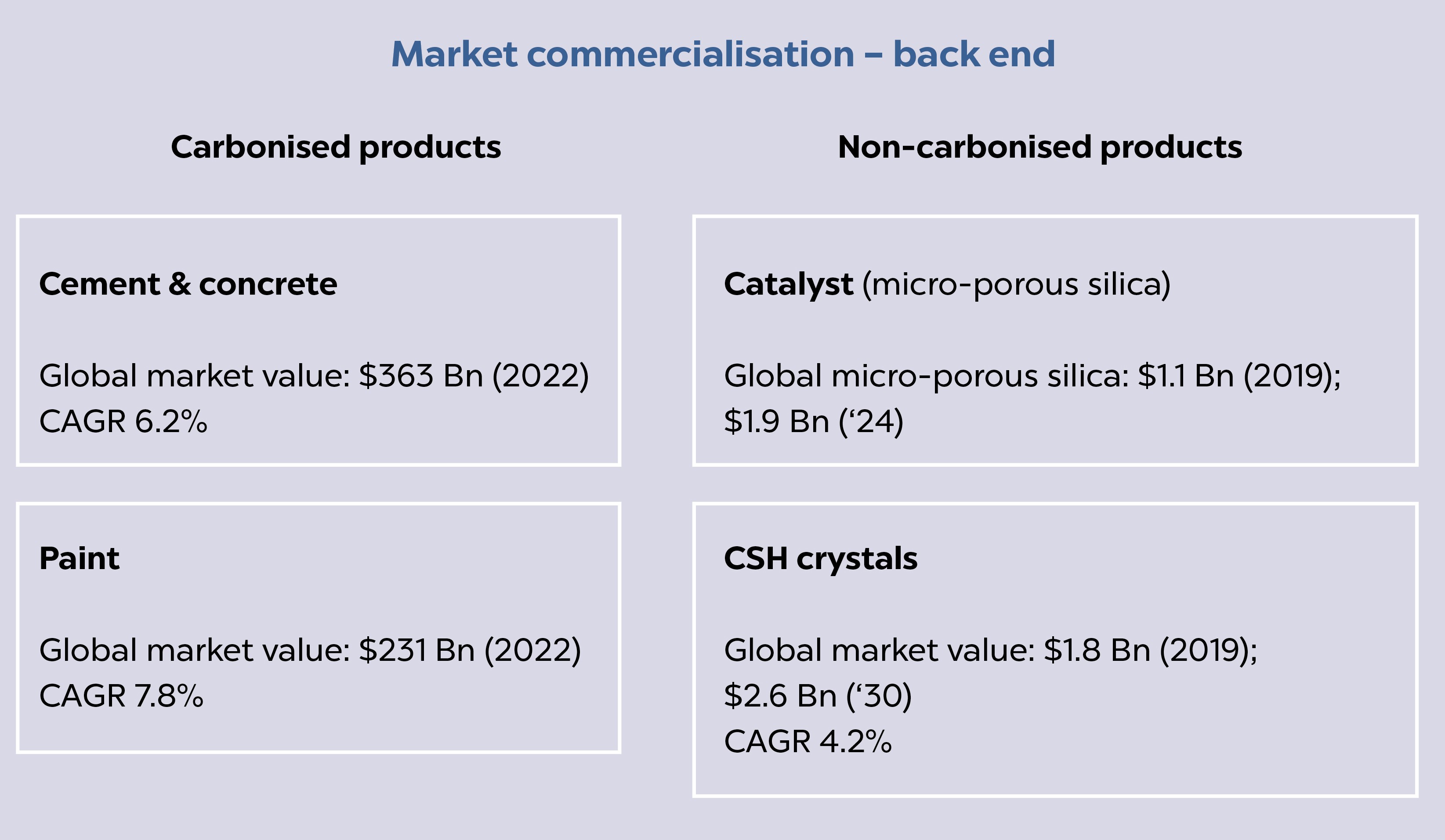

Asbeter's diverse end products portfolio potential enables Asbeter to access the global market for carbonised and non-carbonised Calcium Silicate Hydrate (CSH) minerals. Asbeter will adopt a B2B model to supply calcium silicate and calcium carbonate products to several industries. Our market is typically segmented by customer size and geographical location. Our targeted segment includes large cement, paint, and catalyst industries. Asbeter will provide a new alternative for all operators in the asbestos management and silicate recycling supply chain. Geographically, with the Asbeter site selected in Moerdijk, the Netherlands, that is our first target country. As we are in advanced conversations with parties in France, Germany, Belgium, the UK and Italy, those are Asbeter's next targeted regions. We don't forget Australia either.

Our Targeted Addressable Markets (TAM) are the cement, paint, and catalyst markets. Combining these three markets, our TAM was valued at $594 Bn in 2022 and is expected to grow at an average compound annual growth rate (CAGR) of 7%. There are several factors contributing to the growth of our TAM:

• Rapid urbanisation: As more people move to urban areas, there is a growing demand for new infrastructure.

• Population growth: The world population is increasing rapidly, which is driving the demand for housing, schools, hospitals, and other structures that require cement and paint.

• Industrialisation: As countries become more industrialised, there is a greater demand for industrial structures.

• Infrastructure development: Governments around the world are investing in infrastructure projects.

Overall, the global cement, paint and catalyst markets are likely to continue to grow as the world population continues to increase and economies around the world continue to develop.

The Serviceable Available Market (SAM) for Asbeter is the global market for carbonised and non-carbonised AC minerals produced in an environmentally friendly and sustainable process. The global green cement market size grew from $27.8 Bn in 2022 to $30.7 Bn in 2023 at a compound annual growth rate (CAGR) of 10.6%. The global green coatings market size was valued at $ 123.6 bn in 2022 and is projected to reach $ 155.9 Bn by 2027, growing at a CAGR of 4.8% from 2022 to 2027. In total, our SAM was 151.4 Bn in 2022 and is expected to grow at a CAGR of 7.7%.

Our plan is to first offer our carbonised and non-carbonised AC minerals to the cement market. Asbeter is targeting the first production of silica (calcium silicate or carbonate) in 2025, scaling up with an annual capacity of 124,000 tonnes calcium silicate slurry with 50% dry solids in Q1 2027, therefore our Serviceable Obtained Market (SOM) will be approximately €9 M in 2027.

In short

Asbeter's AC Minerals Process offers the first circular process to reuse 100% raw materials by fully destructing the asbestos fibres present in asbestos cement.

The AC Minerals Process supports a healthier environment and better public health by offering

a safe, affordable, environmentally-friendly and sustainable solution to definitively dissolve

asbestos fibres and, at the same time, return CO2-neutral/negative raw materials to the market.

We can do all this while achieving attractive financial returns.

The main stakeholders in our value chain are the public authorities and investors with

Environmental, Social and Governance criteria. Firstly, public authorities are responsible for

ensuring the safety of people who live and/or work in buildings with asbestos-containing

materials. In addition to these actors, we also serve the building industry, which has high

concerns about the shortage in raw materials. Moreover, there is a growing need to reduce

the industry's emissions. The cement industry, for example, is responsible for about 8%

of CO2-emissions. Asbeter's end products will help reduce such emissions.None of the existing solutions, like the widely used landfilling or thermal treatment at high temperature (>1400C) or emerging plasma technology can process waste asbestos cement in a safe and cost-effective way, which constitutes a heavy pain for public authorities. Asbeter's AC Minerals Process only requires water and energy to dissolve the asbestos fibres in asbestos cement, enabling us to regain the active minerals in a commercially viable way that is also safe and carbon neutral. No expensive and environmentally unfriendly chemicals are necessary. Our reliable and effective solution is backed up by a strong understanding of the treatment process for asbestos cement fibres by our technical team.

We are able to offer our end product as carbon-neutral raw silicate materials.Carbonising our end products will even result in a carbon-negative footprint. The other solutions that currently are being developed, have no asbestos-free end products or a significantly higher CO2-footprint and are much more expensive, so they are not as commercially viable as Asbeter's AC Minerals end products:

ACM calcium silicate hydrate (CSH): carbon zero slurry, powder

ACM calcium carbonate with 89% CO2 uptake: slurry with carbon negative footprint